On April 30th, we had the pleasure of participating in the GS1 Partner Day, where European regulations took center stage. The main focus: the gradual rollout of the Digital Product Passport (DPP), an ambitious initiative born form the ESPR (Ecodesign for Sustainable Products Regulation). This “product passport” aims to track the environmental footprint of goods sold in Europe, whether locally produced or imported.

The DPP: a game-changer for businesses facing European regulations

Europe’s goal is bold: achieve carbon neutrality by 2050. The DPP fits into this vision by requiring the collection, validation, and sharing of precise data on:

– Ecodesign,

– Product durability and reparability,

Material origins,

Recycling or reuse conditions.

Behind this European ambition lies an operational reality: companies will have to make available an enriched, interoperable product sheet, structured according to standards still under construction, and accessible via a unique identifier (such as a QR code, RFID, etc.).

This implies major changes in the way products are developed, manufactured and marketed, as well as a profound transformation of companies’ internal processes. For example, the integration of eco-design criteria is a potential growth lever (up to +20% of sales according to McKinsey*). Production teams will have to adapt their systems to collect and share the traceability data required by the European PLR.

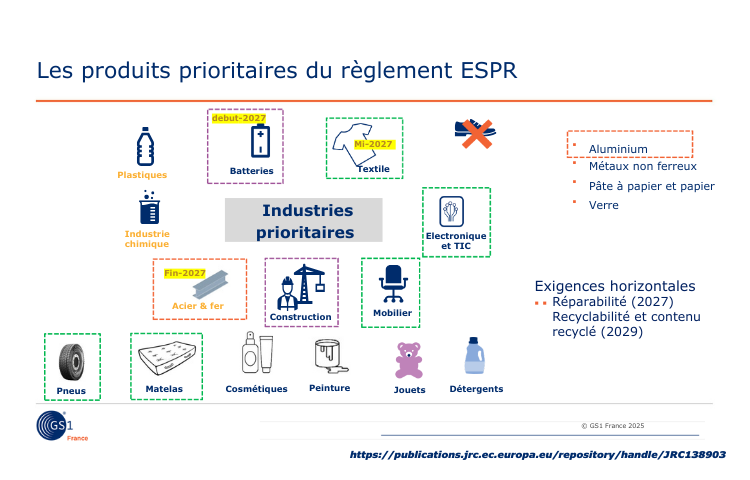

DPP: which sectors will be impacted starting in 2027?

Starting in 2027, several sectors will be required to provide a Digital Product Passport:

– Textiles (excluding footwear),

– Electronics,

– Furniture,

– Tires,

– Mattresses.

Other “intermediate” products such as batteries and steel are also targeted.

From 2023, with the adoption of Regulation (EU) 2023/1542**, the European Union has endorsed the introduction of a digital passport for industrial, electric vehicle and light mobility batteries.

This passport, mandatory from February 2027, will have to group together key information: composition, traceability, carbon footprint, manufacturing conditions, and all accessible via a unique QR code affixed to each battery.

This first wave will serve as a laboratory and set the tone for a gradual roll-out to all physical goods marketed (manufactured or imported) in Europe.

DPP standards: clear guidelines for product compliance across Europe

The technical specifications of the DPP are still being defined (GS1 is currently working on the adoption of its standard by Europe). One thing is certain: data will be at the heart of the system.

Identification, enrichment, traceability and the ability to produce compliant exports all require a robust platform for :

-Aggregate product data,

– Ensure data quality,

– Distribute it through the right channels,

– Keep data up-to-date with product or regulatory changes.

MaPS System: get ready now for compliance

We already support our customers in structuring projects involving product data: compliance, standardization, quality assurance, export in the expected formats(FAB-DIS, GDSN, etc.). The DPP is part of this continuity.

Our platform combines MDM, PIM, and DAM into a solid foundation to:

– Prepare data required for the DPP,

– Integrate sector-specific updates (textile, cosmetics, etc.),

– Ensure regulatory traceability,

– Manage multichannel distribution with customized exports.

The DPP represents a structural shift in product data management — and MaPS System is already your natural enabler for compliance.

A concept already tested before European regulation

We would like to remind you that the concept of a digital product passport did not appear out of nowhere.

Long before European regulation aimed to impose a unified framework, some companies voluntarily pursued transparency, traceability, and circularity to meet customer expectations.

For instance, LVMH launched an experiment in 2021 with the startup Arianee to equip luxury products with a secure digital passport. The goal: track product origin, authenticity, and lifecycle.

This type of initiative shows that brands and manufacturers have not waited for the institutions to initiate virtuous approaches. Even if the formats or standards used up until now did not yet correspond to the expectations of the DPP on a European scale.

Enhanced QR codes and the DPP: what synergies for product traceability?

Another topic discussed at the event was the augmented QR code, already being deployed by a number of pioneers (L’Oréal, Decathlon, etc.). This format will gradually replace the EAN13 barcode, with which it will cohabit for some time to allow time for adaptation.

This next-generation code will carry far more information, including dynamic content tailored to consumers, sellers, or repairers. The type and amount of data (mandatory or optional) will vary by sector.

For the moment, it’s not directly linked to DPP, but we’re touching on the same issues of data quality and structuring. In the medium term, it’s hard to imagine anything other than a QR code linking to a dedicated web page.

The NFC chip? Too expensive and inconsistent with environmental objectives. Two QR codes on the same packaging? Potentially illegible, depending on the size of the packaging. In any case, we’re convinced that responsible digital design doesn’t mean sticking an RFID tag on every nut.

Moral: don’t wait for Brussels to structure your data – it’s already the sinews of war.

—

Ready to prepare today?

Our teams are available to assess your data maturity and propose a tailored roadmap.