How the MaPS System MDM multiplies the efficiency of your ERP

A manufacturer takes several days to create a new supplier in its ERP. A multinational company manages duplicate customer data in 5 different ERP systems. An e-commerce distributor loses sales because its product data sheets are incomplete.

These problems have one thing in common: the absence of master data management.

What is master data management (MDM)?

MDM gathers data from multiple sources such as ERP, CRM, databases, and spreadsheets, unifying it into a centralised system.

It manages master data shared between several applications: products, locations, suppliers, stores, etc.

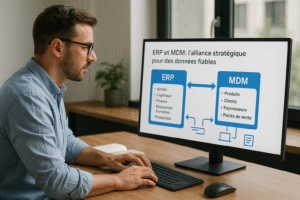

ERP and MDM: the strategic alliance for reliable data

ERP (enterprise resource planning) manages the company’s daily operations—purchasing, logistics, finance, human resources, production, etc.

A true operational foundation, it ensures the circulation of information within different departments and, in its most advanced versions (especially cloud ERP), allows for real-time data integration for instantaneous updating of business processes.

However, ERP is not intended to guarantee data quality, consistency, or unification at the organisational level.

Its data is often fragmented by department or entity, which can generate duplicates, inconsistencies, or delays in updating critical information.

MDM (master data management) complements this system by centralising, structuring, and governing all master data—products, customers, suppliers, points of sale, etc.

It allows for the creation of a unique, reliable source for all applications in the information system.

This principle is based on the concept of the “golden record”, which is a unique and validated master record that ensures the coherence, reliability, and traceability of data throughout the entire company.

Let’s take the example of an item code: the ERP stores the internal code, the unit of measure, and the purchase price. But to sell this product, you need HD photos, multilingual marketing descriptions, technical specifications, sales arguments, etc. It is MaPS System that retrieves the ERP base, enriches this data, and distributes it to all your channels (digital, print, app, etc.).

MaPS System MDM, a performance lever

Designed to integrate into any technical environment, MaPS System strengthens your ERP’s capabilities around four key levers.

Centralised data governance

MaPS System offers a robust and collaborative governance framework, ensuring the quality, consistency, and completeness of data at every stage of its lifecycle.

Thanks to validation workflows, configurable business rules, and automated data quality checks, the platform helps ensure the reliability of information before it is distributed to other systems.

Beyond technical processes, data governance relies on the clear definition of roles and responsibilities: every stakeholder—whether from data, marketing, regulatory, purchasing, or IT teams—has an identified scope of action for the creation, validation, and updating of data.

This approach reinforces the accountability, traceability, and transparency of operations.

Native interoperability

Designed to integrate seamlessly into IS environments, the MaPS System platform relies on open and secure interoperability.

Thanks to its standard connectors (REST API, GraphQL) and its customisable import/export modules, the platform easily communicates with all ERP systems on the market—SAP, Sage X3, Cegid Orli, Generix ACE, Microsoft Dynamics 365, and many others.

The APIs and connectors play a key role in connecting the MDM to enterprise applications (CRM, PLM, DAM, e-commerce, internal business tools, etc.), ensuring fluid and bidirectional data circulation if necessary.

To guarantee the security and compliance of exchanges, MaPS System relies on modern authentication mechanisms ensuring precise access control and complete traceability of API interactions.

This modular and secure approach facilitates the integration of MDM into heterogeneous ecosystems, while preserving the overall performance and consistency of enterprise data.

Omnichannel data distribution

The MDM acts as a central hub between your tools: ERP, CRM, e-commerce, marketplaces, or physical points of sale.

All your data is synchronised and consistent across every channel.

Architecture flexibility

Depending on the organisational structure and the specific needs of each company, MaPS System can be positioned upstream, downstream, or at the core of a multi-ERP environment, in order to harmonise and synchronise data at all levels.

Scenario 1 (most common): ERP → MDM → Channels

The ERP generates the raw data (codes, prices), MaPS System enriches it and distributes it to e-commerce, marketplaces, partners, etc.

Scenario 2 (pre-referencing): MDM → ERP → Channels

The purchasing teams create the product data sheets in MaPS System, validate them collaboratively, and then send them to the ERP once selected.

Advantage: the ERP is not saturated with products undergoing validation.

Typical use cases:

- Supplier validation: a distributor can enrich and validate the characteristics of a new product in the MDM before officially integrating it into the ERP for purchase.

- Dropshipping and sales without stock: an e-commerce distributor can reference its suppliers’ products in MaPS System, publish them immediately on its sales channels (website, marketplaces), and only create the reference in the ERP after the first customer order. This approach allows for rapid testing of new ranges without tying up inventory or overburdening the ERP with unsold references.

Scenario 3: Multi-ERP harmonised by MDM

Several subsidiaries use different ERP systems (SAP, Sage, Cegid). MaPS System becomes the central repository that harmonises and synchronises all data.

Data enrichment: what the ERP does not manage

The ERP focuses on operational processes (purchasing, logistics, finance).

The MDM, however, takes over to structure, enrich, and contextualise this data across all channels.

With MaPS System, it becomes possible to add:

- multilingual labels,

- visuals, technical documents, and regulatory data (DPP, ETIM, FAB-DIS, etc.),

- marketing descriptions and advanced attributes.

This enrichment is essential for e-commerce, catalogues, marketplaces, or internal sales tools.

Example:

- A manufacturer reduced the time to create a supplier from several days to a few minutes thanks to MDM integration.

- An international manufacturer harmonised the management of its third parties in a multi-ERP context, relying on validation workflows shared among several teams.

Use cases: mastering data to optimise the ERP

Multichannel distribution:

A distributor sells on its website, Amazon, Cdiscount, and 50 stores. Without MDM, each channel has different product descriptions and unsynchronised prices.

With MaPS System: a single source, real-time updated everywhere.

Industry / Manufacturing:

A manufacturer manages 10,000 technical references with ETIM specifications, safety data sheets, and certificates. MaPS System centralises this data and automatically feeds the ERP, the sales configurator, and customer catalogues.

ERP migration (SAP S/4HANA):

To maintain operations during the migration to S/4HANA, the MDM can link multiple record structures for the same customer or supplier, allowing synchronisation with legacy systems while generating golden records.

The challenges of an ERP without MDM

When an ERP operates without a master data management (MDM) solution, the management of master data quickly becomes complex and a source of inefficiency. Several recurring difficulties arise:

Data silos

Different departments—sales, purchasing, logistics, finance, marketing—often use separate systems and maintain their own versions of master data (customers, suppliers, products, etc.).

This lack of centralisation leads to information discrepancies, inconsistent decisions, and synchronisation delays between services.

Manual and time-consuming processes

Without automation, the updating and validation of master data rely on manual entry in the ERP or shared Excel files.

These practices increase the risk of errors, slow down business processes, and make the traceability of modifications difficult.

Inconsistent standards

In the absence of centralised governance, each department adopts its own input conventions:

different formats, unharmonised units of measurement, divergent tax codes, or non-standardised product labels.

These structural inconsistencies harm overall data quality, complicate exchanges between systems, and distort analyses.

Why combining MDM and ERP is becoming essential?

Internationalisation, channel diversification, and external growth complicate information systems.

ERP alone quickly reaches its limits when faced with the volume, variety, and critical value of the data.

Integrating an MDM like MaPS System then becomes a lever for sustainable performance, at several levels:

- Harmonise a multi-ERP environment: a unique repository for unified data.

- Improve data quality: normalisation, control, enrichment, and overall consistency.

- Reduce operational costs and errors: elimination of duplicates, automation of validations.

- Secure ERP migration projects: clean database, ready for take-over.

- Ensure compliance and customer experience: data compliant with standards (DPP, ETIM, FAB-DIS) and consistent across all touchpoints.

When does MDM become essential?

For an SME with a limited catalogue and simple processes, an ERP may be sufficient to orchestrate operations.

However, as soon as the company enters a phase of complexity, adopting an MDM like MaPS System becomes essential.

Warning signs:

- More than 5,000 product references to manage,

- Three or more sales channels (for example: B2B, B2C, marketplaces),

- Presence of one or more ERP systems (subsidiaries, external growth, multi-entities),

- Ongoing or upcoming ERP migration project,

- Need for regulatory or normative compliance (DPP, ETIM, FAB-DIS, GS1, etc.).

Why these thresholds?

- Beyond several thousand products, manual or fragmented management quickly becomes unmanageable and a source of errors—which is well documented in MDM best practices.

- Multiplying channels or entities multiplies data sources, duplicates, and inconsistencies.

- An ERP migration or a multi-ERP context requires reliable and centralised data governance—a natural role for MDM.

Regulatory obligations strengthen the requirement for data quality, traceability, and consistency, types of benefits provided by MDM.

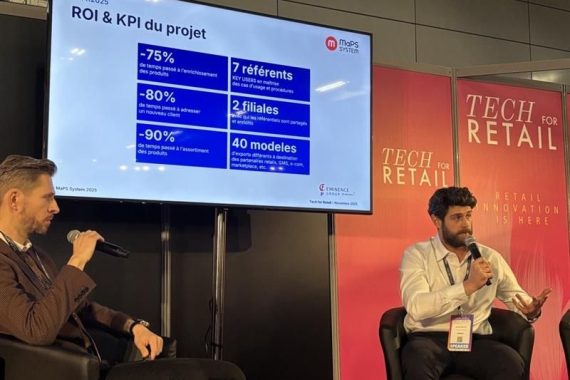

The concrete benefits of an ERP connected to MaPS System

- Data consistency across all systems

- Reduction of errors and duplicates

- Improved reliability of business processes

- Agility gain to support growth

- Team alignment around mastered data

- Optimised preparation for migration or international expansion projects

And finally

Far from replacing the ERP, MaPS System MDM complements and strengthens it.

It becomes the central hub of the information system, ensuring that all data used in business processes is reliable, structured, and synchronised.

Combining ERP and MDM is choosing efficiency, consistency, and long-term performance.

Ready to transform your information system? Discover how our clients reduced their time-to-market by 40%, eliminated 95% of data duplicates, and harmonised their multi-ERP environments.”